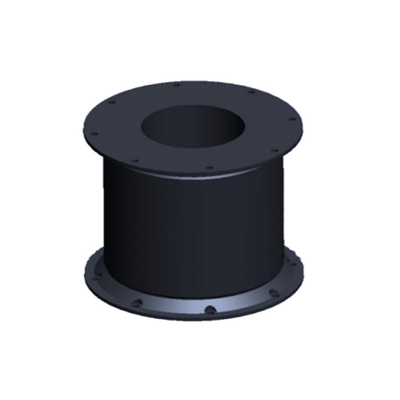

Geavanceerde schokabsorptie kegel fender UV-bestendige structuur stabiele prestaties

Beschrijving

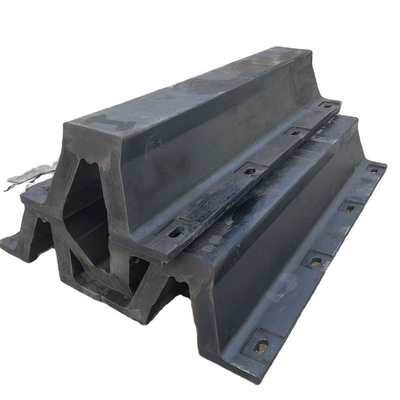

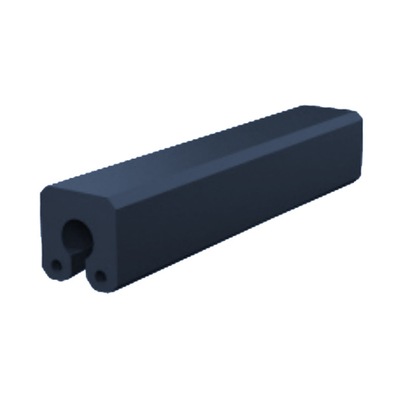

De Cone Rubber Fender is een hoogwaardige scheepsfender die is ontworpen voor havens en offshore-faciliteiten waar betrouwbare energie-absorptie en lage reactiekracht van cruciaal belang zijn.De conische geometrie zorgt voor een efficiënte compressie tijdens de botsing met het vaartuig.Het compacte ontwerp zorgt voor een hoge energie-absorptie ten opzichte van zijn voetafdruk.het geschikt maken voor havens met beperkte ruimte of waar meerdere ligplaatsen tegelijkertijd worden gebruikt.

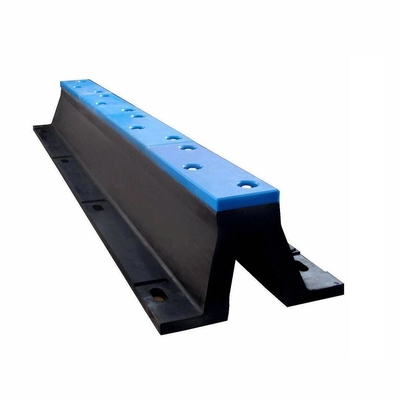

Gebouwd van hoogwaardige natuurlijke en synthetische rubber met meerdere versterkingslagen, bieden Cone Fenders uitzonderlijke duurzaamheid, elasticiteit en weerstand tegen ozon, UV,en blootstelling aan zout waterHet modulaire ontwerp maakt de optionele integratie van stalen steunplaten en UHMW-PE-beugels mogelijk, waardoor de wrijving wordt verminderd en de prestaties op lange termijn worden verbeterd.

Gevalstudie: Offshore-aanvoerbasis ¢ West-Afrika

Een offshore-voorraadbasis die bemanningsoverdrachtvaartuigen en voorraadvaartuigen vervoert, had een schuttersysteem nodig dat onder sterke getijdenstromen regelmatige ligplaatsen kon weerstaan.Eerdere schutters hadden te maken met vroeg slijtage en hoge onderhoudskosten als gevolg van herhaalde hoge-energie-inslagen en slijtage in zoutwater..

Hongruntong Marine leverde Cone Rubber Fenders versterkte stalen platen en laag wrijvings UHMW-PE gevelplaten.en de uitlijning is geverifieerd om een optimale impactprestatie te garanderen.

Na 14 maanden toonden de gegevens een vermindering van 38% van de reactiekrachten van de kadewand en een aanzienlijk gladder varen.en minimaal onderhoud vereistDe exploitanten rapporteerden een verbeterde veiligheid voor schepen en personeel, wat de doeltreffendheid van het conische schutterontwerp onder uitdagende omstandigheden aan zee benadrukt.

Specificaties

| Productnaam |

Schroeven van conige rubber |

| Merknaam |

Hongruntong Marine |

| Materiaal |

NR van hoge kwaliteit |

| Standaard |

PIANC, HGT |

| Gezichtskussens |

UHMW-PE beschikbaar |

| Certificaten |

BV, ABS, DNV, LR, SGS, RS, CCS |

| OEM / ODM |

Welkom. |

| Verpakkingsgegevens |

Plastieksakken dan naar de pallet / op uw verzoek |

| Productiecapaciteit |

3000 stuks per maand |

| Levertyd |

7 dagen voor prototype gereedschap & monsters, 14 dagen voor productie vorm, 14-28 dagen voor MOQ |

| Betalingsvoorwaarden |

T/T, L/C, Paypal, Western Union |

| Specificatie van rubber |

ASTM D2000, SAE J200 |

| Model |

H |

h |

F |

D |

Q |

W |

D-m |

D-n |

| Kegel |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

| HM-CRF300 |

300 |

13.5 |

255 |

450 |

195 |

405 |

M16 |

20 |

| HM-CRF350 |

350 |

25 |

300 |

570 |

235 |

510 |

M20 |

25 |

| HM-CRF400 |

400 |

18 |

340 |

600 |

260 |

540 |

M20 |

25 |

| HM-CRF500 |

500 |

25 |

425 |

750 |

325 |

675 |

M24 |

30 |

| HM-CRF600 |

600 |

27 |

510 |

900 |

390 |

810 |

M24 |

30 |

| HM-CRF700 |

700 |

32 |

585 |

1050 |

455 |

945 |

M30 |

38 |

| HM-CRF800 |

800 |

36 |

680 |

1200 |

520 |

1080 |

M36 |

44 |

| HM-CRF900 |

900 |

41 |

765 |

1350 |

585 |

1215 |

M36 |

44 |

| HM-CRF1000 |

1000 |

45 |

850 |

1500 |

650 |

1350 |

M42 |

56 |

| HM-CRF1050 |

1050 |

55 |

1030 |

1680 |

900 |

1530 |

M36 |

44 |

| HM-CRF1100 |

1100 |

50 |

935 |

1650 |

715 |

1485 |

M42 |

50 |

| HM-CRF1150 |

1150 |

52 |

998 |

1725 |

750 |

1550 |

M42 |

56 |

| HM-CRF1200 |

1200 |

54 |

1020 |

1800 |

780 |

1620 |

M42 |

50 |

| HM-CRF1300 |

1300 |

59 |

1105 |

1950 |

845 |

1755 |

M48 |

60 |

| HM-CRF1400 |

1400 |

66 |

1190 |

2100 |

930 |

1890 |

M48 |

60 |

| HM-CRF1600 |

1600 |

72 |

1360 |

2400 |

1060 |

2160 |

M48 |

70 |

| HM-CRF1800 |

1800 |

78 |

1530 |

2880 |

1190 |

2430 |

M56 |

76 |

| HM-CRF2000 |

2000 |

80 |

1900 |

3200 |

1540 |

2920 |

M56 |

76 |

Kenmerken

Geoptimaliseerde energie-absorptie en belastingverdeling

Het kegelvormige profiel zorgt voor geleidelijke vervorming bij botsing met het vaartuig, waardoor krachten efficiënt worden verdeeld over de schutter, waardoor de reactiekracht op de kade wordt verminderd en lokale spanning wordt voorkomen.bescherming van zowel de structuur als de romp van het schipDe hoge verhouding energie/voetafdruk zorgt voor prestaties zelfs in compacte dokgebieden.

Hoogwaardig rubber en milieuvriendelijkheid

Kegelvoeters worden geproduceerd met behulp van exclusieve natuurlijke en synthetische rubbermengsels die bestand zijn tegen ozon, UV en zout water.het mogelijk maken van duizenden ligplaatsen zonder verlies van prestatiesHet materiaal behoudt de elasticiteit en de energie-absorptie tijdens langdurige blootstelling aan harde mariene omgevingen.

Structurele versterking en stabiliteit

Interne synthetische weefsellagen in combinatie met optionele gegalvaniseerde of roestvrijstalen steunplaten zorgen voor stabiliteit onder compressie en hoekinslagen.Versterkingen zorgen voor een consistente vorm en energie-absorptiecapaciteit, zelfs onder herhaalde hoge belastingomstandigheden, waardoor de levensduur en betrouwbaarheid worden verlengd.

Modulair ontwerp voor flexibele installatie

De modulaire constructie maakt snelle installatie, vervanging en aanpassing aan de specifieke eisen van de ligplaats mogelijk.Voorgeboorde gaten en gestandaardiseerde bevestigingssystemen vereenvoudigen de montage op betonnen en stalen dokken, waardoor de operationele stilstandstijden en de onderhoudskosten worden verminderd.

Toepassingen

Offshore-voorzieningsplaatsen

Beschermt bemanningsoverdrachtsschepen en bevoorradingsschepen tegen herhaalde hoge-energie-inslagen, waardoor een soepele en veilige aanleg wordt gewaarborgd.

Bulk- en containerterminals

Het absorbeert efficiënt energie tijdens het aanmeren van grote vrachtschepen en containerschepen, waardoor de spanning op de kadewand en de romp wordt verminderd.

Zeehavens en defensiehavens

Zorgt voor een veilige ligplaats voor militaire schepen, patrouilleboten en ondersteuningsschepen, waarbij de operationele gereedheid en structurele integriteit worden gehandhaafd.

Waarom Hongruntong Marine?

Geavanceerd ontwerp en engineering optimalisatie

Hongruntong maakt gebruik van eindige-elementen analyse (FEA) en energie-absorptie simulaties om schutters te ontwerpen die de krachtverdeling, slagweerstand en duurzaamheid te optimaliseren.Elke beugel is afgestemd op het type vaartuig., ligplaats afmetingen en getijdenomstandigheden om maximale efficiëntie en veiligheid te garanderen.

Hoogwaardige materialen en uitstekende productie

Eigen rubberverbindingen, precieze vulcanisatie en versterkte meerlagige constructie zorgen voor consistente materiaal eigenschappen, hoge treksterkte en superieure elasticiteit.Deze eigenschappen zorgen voor duurzaamheid en vermoeidheidsbestandheid op lange termijn, hoogfrequente ligplaatsen.

Op maat gemaakte oplossingen voor specifieke operationele behoeften

Kegelfenders kunnen worden aangepast in grootte, basisdiameter, geconfronteerde pads en montage systeem om te voldoen aan ligplaats lay-out, vaartuig klasse, en de omgevingsomstandigheden.efficiëntie, en levensduur, met optionele beschermende elementen zoals stalen steunplaten en wrijvingsreducerende panelen.

Wereldwijde service- en onderhoudsondersteuning

Hongruntong biedt wereldwijde technische ondersteuning, waaronder installatietoezicht ter plaatse, prestatiebewaking, inspectie, renovatie en levering van onderdelen.Onderhoudsprogramma's en technische begeleiding zorgen voor de betrouwbaarheid van de beugel, downtime te minimaliseren en de levensduur te verlengen.

Veelgestelde vragen

1Wat is de verwachte levensduur van kegelrubberfenders?

Typisch 12-20 jaar, afhankelijk van de bedrijfsintensiteit, de omgevingsomstandigheden en de onderhoudspraktijken.

2Zijn cone fenders geschikt voor hoogfrequente ligplaatsen?

Ja, de conische geometrie verdeelt de slagenergie efficiënt, waardoor frequente ligplaatsen mogelijk zijn zonder structurele compromissen.

3Kunnen er voor extra bescherming geconfronteerde pads worden toegevoegd?

Ja, de optioneel beschikbare UHMW-PE pads verminderen de wrijving, beschermen de romplaag en verbeteren de prestaties van de schutter.

4Welke montageopties zijn beschikbaar?

Stalen steunplaten zijn verkrijgbaar in gegalvaniseerd of roestvrij staal voor betonnen of stalen kadeinstallaties, die een veilige bevestiging en corrosiebestendigheid bieden.

5Hoe vaak moeten de schutters worden geïnspecteerd?

Visuele inspectie om de zes maanden, met jaarlijkse gedetailleerde controles op slijtage van het oppervlak, integriteit van de montage en stabiliteit van de versterking.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!