Dock Fenders Heavy Duty Construction Outstanding Abrasion Resistance Low Reaction Force

Description

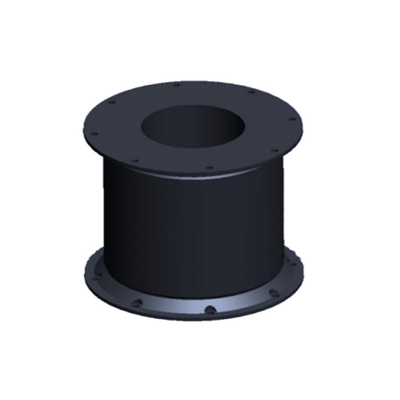

The Cylindrical Marine Fender is one of the most traditional and versatile fender types used in modern ports, shipyards, and offshore facilities. Designed with a simple yet highly efficient cylindrical body, this fender provides reliable energy absorption and low reaction forces during vessel berthing. Its round cross-section allows even distribution of impact pressure, making it ideal for a wide range of quay walls and ship hull shapes.

Manufactured from premium-grade natural and synthetic rubber compounds, Hongruntong’s Cylindrical Marine Fenders deliver exceptional durability, elasticity, and weather resistance. Each fender is extruded and vulcanized under strict quality control standards to ensure uniform wall thickness, consistent density, and precise energy absorption performance.

The cylindrical shape allows flexible mounting configurations—hung vertically, horizontally, or suspended by chains and ropes. This adaptability makes the fender suitable for different berthing structures and vessel sizes, from fishing boats to oil tankers.

Case Study – Port of Antwerp, Belgium

In 2021, the Port of Antwerp upgraded one of its cargo terminals to handle both medium-sized cargo ships and heavy fuel tankers. The existing block-type rubber fenders showed high reaction loads and visible hull marks on newly painted vessels. The port authority required a fender system that could minimize hull stress while maintaining high energy absorption over long service cycles.

Hongruntong Marine supplied Cylindrical Fenders (Ø1000 × 5000 mm) made from a high-resilience rubber compound with steel mounting chains and frontal protection pads. The fenders were installed horizontally along the quay wall using chain-tension systems that allowed natural rolling during contact, effectively reducing friction.

After 18 months of continuous operation, inspections revealed a 47% decrease in vessel hull abrasion and a 30% reduction in maintenance downtime compared to the previous system. The terminal reported smoother berthing operations even under rough weather conditions.

The project highlighted Hongruntong’s ability to design and manufacture customized cylindrical fender systems optimized for specific port requirements—ensuring operational efficiency, safety, and longevity.

Specifications

| Product Name |

Cylindrical Marine Fenders |

| Material |

Natural Rubber, NBR, EPDM |

| Standard |

PIANC2002, HGT2866-2016 |

| Size |

ID: 75-1000mm; OD: 150-2000mm or Customized |

| Color |

Red, Yellow, Blue, Black, White etc |

| Hardness |

55 Shore A |

| Processing Service |

Moulding, Cutting |

| Tensile Strength |

≥18 MPA |

| Elongation at break |

≥400% |

| Feature |

Environmentally Friendly |

| Application |

Dock, Port, Quay, Boat |

| Advantage |

High Resilience |

| Quality |

Long Lasting Life |

| Function |

Shock Absorption |

| Service |

CustomOEM ODM Service |

| Packaging |

Inner Packing: A. Separate, Each Piece with a Care Label + Tarpaulin

B. Batch, Each Piece is packed in a Transparent Plastic Film

Outer Packing: Tarpaulin or Plastic Film

|

| Model |

Length |

Inside Diameter |

Outside Diameter |

| Cylindrical |

[mm] |

[mm] |

[mm] |

| HM-CMF150 |

Customized Length |

75 |

150 |

| HM-CMF200 |

100 |

200 |

| HM-CMF250 |

125 |

250 |

| HM-CMF300 |

150 |

300 |

| HM-CMF400 |

200 |

400 |

| HM-CMF500 |

250 |

500 |

| HM-CMF600 |

300 |

600 |

| HM-CMF700 |

350 |

700 |

| HM-CMF800 |

400 |

800 |

| HM-CMF900 |

450 |

900 |

| HM-CMF1000 |

500 |

1000 |

| HM-CMF1100 |

550 |

1100 |

| HM-CMF1200 |

600 |

1200 |

| HM-CMF1400 |

700 |

1400 |

| HM-CMF1600 |

800 |

1600 |

| HM-CMF700 |

850 |

1700 |

| HM-CMF800 |

900 |

1800 |

| HM-CMF1900 |

950 |

1900 |

| HM-CMF2000 |

1000 |

2000 |

Features

Superior Energy Absorption with Low Reaction Force

The circular cross-section of the Cylindrical Fender offers exceptional energy absorption capability while maintaining minimal reaction pressure on vessel hulls. This balance is essential for ports handling vessels of varying sizes. The flexible structure allows controlled deformation during impact, dissipating kinetic energy efficiently without causing structural stress on the quay or ship.

Flexible Installation and Versatility

Cylindrical Fenders can be installed horizontally, vertically, or diagonally depending on berth configuration. They can be chain-hung, supported by brackets, or connected with steel rods for long continuous applications. This adaptability makes them suitable for dolphins, jetties, pontoon berths, and ship-to-ship operations. Hongruntong provides complete mounting accessories and drawings for precise fitment.

High Quality Marine Rubber Composition

Every fender is produced using carefully selected rubber compounds with high tensile and elongation strength. The formulation ensures resistance to ozone, saltwater, oil, and temperature variations. Advanced curing and vulcanization guarantee uniform density and long-lasting resilience even in high-frequency berthing zones.

Proven Long Service Life and Easy Maintenance

With their simple shape and solid construction, Cylindrical Fenders require minimal maintenance. The absence of complex metal inserts reduces corrosion risk and simplifies periodic inspection. Typical service life exceeds 10 years under normal operating conditions, making them one of the most cost-effective fendering solutions available.

Applications

Multipurpose Cargo Terminals

Cylindrical Fenders provide flexible energy absorption for vessels of varying tonnage, ensuring smooth berthing for cargo and container ships.

Tanker Berths and Oil Jetties

Their high resilience and low reaction pressure make them ideal for protecting sensitive hull surfaces of tankers and LNG carriers.

Fishing Harbors and Ferry Docks

Easy installation and low maintenance make them a perfect choice for small to medium-sized vessels operating in frequent berthing cycles.

Why Choose Hongruntong Marine

Advanced Manufacturing and Material Expertise

Hongruntong Marine utilizes precision extrusion and hot vulcanization technology to ensure consistent product quality. Rubber compounds are optimized for tensile strength, tear resistance, and deformation recovery, guaranteeing superior impact performance across temperature ranges.

Customized Engineering Solutions

Our team works closely with clients to design tailor-made fender systems. From selecting diameters and lengths to specifying mounting accessories and chain arrangements, every detail is engineered for maximum efficiency and safety.

Global Quality Certifications and Testing

All fenders undergo rigorous testing including compression, shear, ozone, and aging resistance. Hongruntong adheres to ISO 9001, ISO 17357, and PIANC guidelines, ensuring full compliance with international marine safety standards.

Comprehensive Project Support and After-Sales Service

We provide complete technical documentation—drawings, test reports, and performance data—along with on-site supervision and after-sales inspection. Our global logistics network ensures fast delivery and responsive service to clients in over 60 countries.

FAQ

1. What sizes are available for Cylindrical Fenders?

Standard diameters range from 150 mm to 2500 mm, with custom lengths available upon request.

2. Can the fenders be used for floating docks?

Yes, they can be suspended or attached with chain systems, making them ideal for floating structures.

3. How are they fixed to the quay wall?

Installation methods include chain-hung, bracket-mounted, or through-rod systems depending on berth design.

4. Do they require regular maintenance?

Only basic visual inspections and occasional cleaning are needed. The rubber material resists wear and UV exposure.

5. Can Hongruntong supply accessories and mounting hardware?

Yes, we provide complete kits including chains, shackles, brackets, and bolts for ready installation.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!