Hongruntong Marine Mooring Bollards zijn ontworpen als premium mooringoplossingen voor complexe en hoogwaardige maritieme infrastructuurprojecten.Ontworpen om aan de strenge eisen van moderne havens te voldoenDeze bollarden combineren uitzonderlijke structurele sterkte met flexibele ontwerpadaptabiliteit.

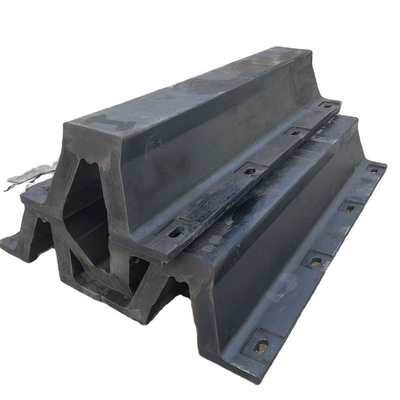

Het productassortiment bestrijkt nominale capaciteiten van 50KN tot 2000KN en kan verder worden aangepast aan unieke belastinggevallen, funderingsbeperkingen en omgevingsomstandigheden.met een breedte van niet meer dan 50 mm, de bollarden hebben een solide constructie van één stuk die zorgt voor een uniforme belastingoverdracht en een superieure weerstand tegen vervorming, vermoeidheid en toevallige botsingen.

Geavanceerde oppervlaktebehandelingssystemen en precisiebewerking zorgen voor uitstekende corrosiebestendigheid, slijtvastheid en lange termijn dimensionale stabiliteit.terminals met beperkte ruimteDe Hongruntong Marine Mooring Bollards leveren betrouwbare prestaties, verbeterde veiligheid en een lange levensduur.ondersteuning van de efficiënte exploitatie van cruciale maritieme infrastructuur.

Case Study Speciaal LNG Terminal Mooring Project

Een nieuw ontwikkelde LNG-invoerterminal vereiste een op maat gemaakte ligplaats die in staat was grote LNG-carriers van 140.000 tot 210.000 DWT te verwerken.hoge blootstelling aan wind, en strenge veiligheidsvoorschriften, werden standaardverbindingsoplossingen als onvoldoende beschouwd.

Hongruntong Marine was commissioned to design and supply a set of 2000KN heavy-duty mooring bollards with customized base dimensions and enhanced corrosion protection suitable for cryogenic and coastal environmentsDe bollarden werden geïntegreerd in betonnen scheepsconstructies die ontworpen waren om extreme moerkrachten tijdens het laden en lossen te weerstaan.

Na de ingebruikname meldde de terminal een stabiele aanlegprestatie onder sterke windomstandigheden en verbeterde veiligheidsmarges tijdens LNG-overdrachten.Onafhankelijke inspecties bevestigden uitstekende structurele integriteit en coating prestatiesHet project toonde de capaciteit van Hongruntong Marine aan om betrouwbare, herhaalbare oplossingen te bieden voor haveninfrastructuur met een hoog risico en een hoge waarde.

SpecifiekVerklaringen

| Productnaam |

Deeltjes voor het aanmeren |

| Merknaam |

Hongruntong Marine |

| Materiaal |

Koolstofstaal, roestvrij staal, legering, ductiel ijzer |

| Kleur |

Zwart en de eisen van de klant |

| Vorm |

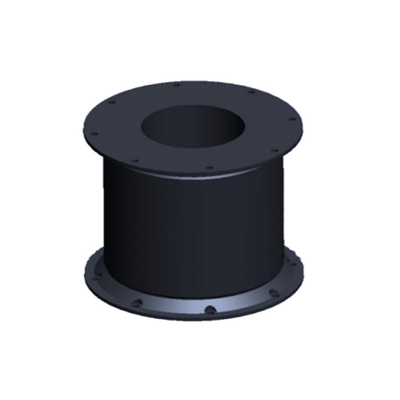

Tee, Horn, Pillar, enz. |

| Standaard |

ISO 13797:2020, PIANC2002 |

| Oppervlaktebehandeling |

Galvaniserend sproeien |

| Toepassing |

haven, dok, kade, enz. |

Productkenmerken

Volledig aanpasbaar ontwerp

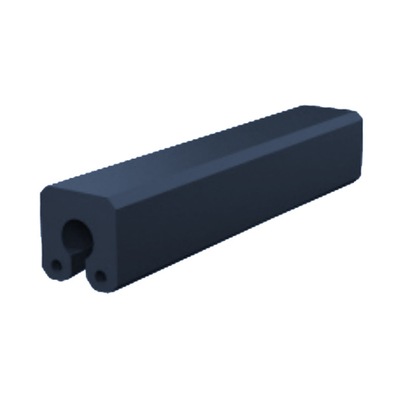

Elke bollard kan worden afgestemd op de belasting, geometrie, basisconfiguratie en materiaalkwaliteit.met inbegrip van ongebruikelijke ladingsrichtingen, beperkte installatieruimte of niet-standaard funderingsontwerpen.

Uitzonderlijke structurele integriteit

De één-stuk gegoten structuur elimineert lasnaadingen en potentiële zwakke punten. Versterkte spanningszones en geoptimaliseerde laadpaden zorgen voor een veilige prestatie onder extreme statische en dynamische verankeringskrachten.

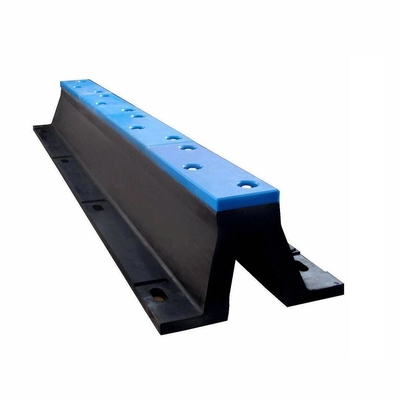

Hoogwaardige oppervlaktebehandelingssystemen

Geavanceerde coatings bieden een lange termijn bescherming tegen corrosie, slijtage, blootstelling aan UV-straling en chemische aanvallen.Deze behandelingen zijn vooral geschikt voor agressieve omgevingen zoals LNG-terminals., chemische havens en tropische kustgebieden.

Compatibiliteit met geavanceerde mooringsystemen

De bollarden zijn ontworpen om naadloos te kunnen worden geïntegreerd met moderne ligplaatsen, waaronder geautomatiseerde ligplaatsen en synthetische touwen met hoge prestaties.

Toepassingen

Gespecialiseerde energie- en LNG-terminals

Ideaal voor LNG-, LPG- en energieterminals die hoge veiligheidsnormen en op maat gemaakte mooringoplossingen vereisen.

Hoogwaardige handelshavens

Gebruikt in vlaggenschipcontainerhavens en internationale hubs waar betrouwbaarheid op lange termijn en infrastructuurbescherming van cruciaal belang zijn.

Beperkte of uitdagende ligplaatsen

Geschikt voor havens met ruimtebeperkingen, complexe ladingsroutes of extreme blootstelling aan het milieu.

Waarom Hongruntong Marine?

Expertise op het gebied van aangepaste scheepsbouw

Hongruntong Marine is uitstekend in het leveren van op maat gemaakte oplossingen voor complexe en veeleisende maritieme projecten.

Sterke projectuitvoeringscapaciteit

Van het ontwerpconsult tot de uiteindelijke levering worden de projecten ondersteund door ervaren ingenieurs en gecoördineerde productieplanning.

Hoogwaardige materialen en productie

Er worden uitsluitend gecertificeerde grondstoffen en gecontroleerde gietprocessen gebruikt om een consistente productkwaliteit te garanderen.

Langetermijnpartnerschap en steun

Uitgebreide technische documentatie, inspectieondersteuning en levenscyclusdiensten zorgen voor een duurzaam succes van het project.

Veelgestelde vragen

1Kunnen bollards volledig worden aangepast voor speciale projecten?

Ja, afmetingen, draagkracht, materiaal en coatings kunnen allemaal worden aangepast aan de eisen van het project.

2Zijn deze bollards geschikt voor LNG- en energieterminals?

Ja, ze zijn ontworpen om te voldoen aan de eisen inzake veiligheid en duurzaamheid van energiegerelateerde havenfaciliteiten.

3Kunnen bollards worden geïntegreerd met geautomatiseerde ligsystemen?

Ze kunnen worden ontworpen om samen te werken met geautomatiseerde en hybride mooringoplossingen.

4Welke documentatie wordt voor grote projecten verstrekt?

Er worden gedetailleerde tekeningen, materiaalcertificaten, inspectieverslagen en kwaliteitsdocumenten verstrekt.

5Hoe wordt de prestatie op lange termijn gewaarborgd?

Door een robuust ontwerp, hoogwaardige materialen, geavanceerde coatings en uitgebreide technische ondersteuning.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!