Hongruntong Marine Mooring Bollards zijn ontwikkeld voor zware en risicovolle mariene omgevingen waar extreme belastingen en moeilijke omstandigheden een superieure structurele sterkte en betrouwbaarheid vereisen.ontworpen voor gebruik in offshore terminalsDeze bollarden zorgen voor een veilige aanlegprestatie onder continue hoge spanning en dynamische omgevingskrachten.

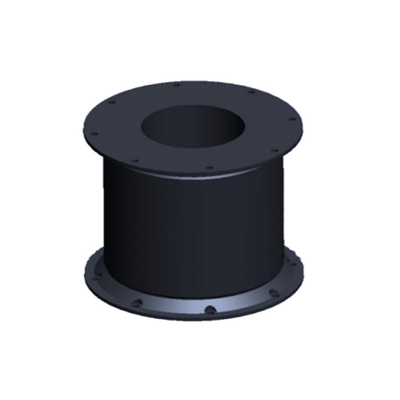

De bollarden zijn verkrijgbaar in belastingscapaciteiten van 100KN tot 2000KN en zijn vervaardigd met behulp van hoogwaardig gegoten staal met een verbeterde wanddikte en versterkte laadpaden.De stevige één-stuk gietstructuur zorgt voor een gelijkmatige krachtverdeling van de mooringlijn door de bollard en in de fundering, waardoor het risico op scheuren of vervorming bij piekbelastingen wordt verminderd.

Ontworpen voor langdurige blootstelling aan zout water, UV-straling, temperatuurschommelingen en zware slijtage, leveren Hongruntong Marine Mooring Bollards uitzonderlijke duurzaamheid, veiligheid,en operationele stabiliteitZe zijn een ideale keuze voor kritieke infrastructuur waar falen geen optie is.

Gevalstudie Offshore Supply Base Docking System

Een offshore-voorzieningsplatform voor platforms (PSV's) en trekboten (AHTS's) voor ankervervoer in de omvang van 10.000 ¢25,000 DWT vereiste een verbeterde liggapparatuur om te kunnen omgaan met verhoogde lijnbelastingen tijdens slechte weersomstandighedenBestaande bollarden vertoonden tekenen van vermoeidheid en laagfalen als gevolg van voortdurende blootstelling aan sterke winden en golven.

Hongruntong Marine leverde 1600KN zware gietijzeren mooringballasten met versterkte basis en verbeterde corrosiebescherming.De bollarden werden geïnstalleerd op een nieuw versterkte kade die is ontworpen voor offshore logistieke operaties.

Na twee jaar gebruik vertoonden de bollarden een uitstekende structurele stabiliteit zonder zichtbare vervorming of vermoeidheidspraken.De exploitanten rapporteerden een verbeterde veiligheid van de ligplaatsen tijdens stormomstandigheden en minder nood aanpassingen, waarbij de betrouwbaarheid van de oplossing voor offshore-voorzieningsplaatsen en vergelijkbare zware toepassingen wordt bevestigd.

Specificaties

| Productnaam |

Deeltjes voor het aanmeren |

| Merknaam |

Hongruntong Marine |

| Materiaal |

Koolstofstaal, roestvrij staal, legering, ductiel ijzer |

| Kleur |

Zwart en de eisen van de klant |

| Vorm |

Tee, Horn, Pillar, enz. |

| Standaard |

ISO 13797:2020, PIANC2002 |

| Oppervlaktebehandeling |

Galvaniserend sproeien |

| Toepassing |

haven, dok, kade, enz. |

Productkenmerken

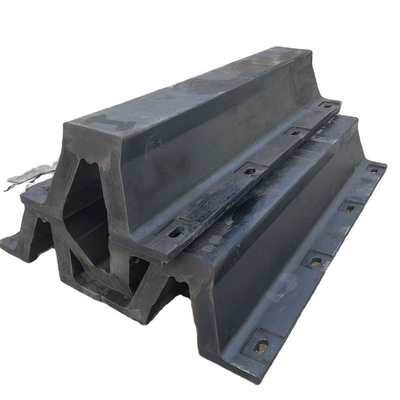

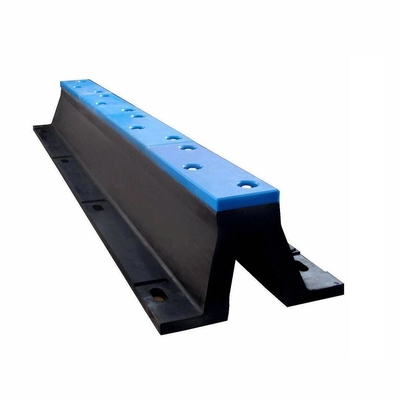

Ontwerp van de zware ladingverdeling

De bollarden zijn ontworpen met dikkere dwarsdoorsneden en versterkte halsgebieden om extreme aanlegkrachten veilig in de fundering over te dragen.Dit ontwerp vermindert de spanningsconcentratie en verbetert de algemene veiligheid van de structuur.

Hoogsterke gietijzeren constructies

Met behulp van hoogwaardig gegoten staal bieden de bollards een superieure treksterkte, slagweerstand en vermoeidheidsduur, waardoor ze geschikt zijn voor hoogbelastingen en lange verankeringsscenario's.

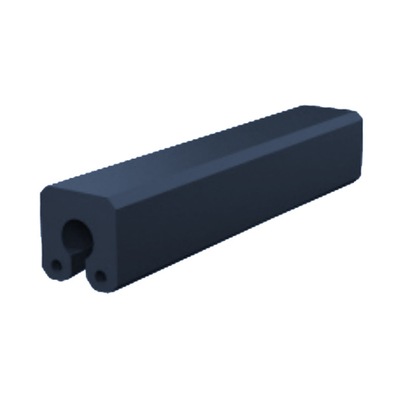

Geavanceerde bescherming tegen corrosie en slijtage

Gespecialiseerde coatingsystemen van maritieme kwaliteit beschermen de bollarden tegen zoutwatercorrosie, mechanische slijtage en blootstelling aan UV, waardoor ze op lange termijn in blootgestelde omgevingen kunnen functioneren.

Stabiliteit onder dynamische omgevingskrachten

De bollards zijn ontworpen om onder de combinatie van wind, golven en stromingen betrouwbaar te werken.

Toepassingen

Offshore terminals en bevoorradingscentrales

Ideaal voor offshore logistieke hubs die boorplatformen en offshore bouwvaartuigen ondersteunen.

Zware industriële havens

Geschikt voor staalfabrieken, LNG-terminals en energiefaciliteiten die een hoog vermogen hebben.

Blootgestelde kustplaatsen

Gebruikt in havens met sterke stromingen, sterke winden of blootstelling aan open zee waar een verhoogde veiligheidsmarge vereist is.

Waarom Hongruntong Marine?

Expertise in zware marineapparatuur

Hongruntong Marine is gespecialiseerd in het ontwerpen en leveren van apparatuur voor veeleisende mariene en offshore omgevingen.

Robuuste techniek en aanpassing

Elke bollard kan worden ontworpen om aan specifieke belastinggevallen, omgevingsomstandigheden en funderingseisen te voldoen.

Bewezen prestaties onder moeilijke omstandigheden

Producten worden getest en gevalideerd door middel van praktijkaanpassingen in offshore- en industriële havens.

Betrouwbaarheid en ondersteuning op lange termijn

Uitgebreide technische ondersteuning en levenscyclusdiensten zorgen voor duurzame prestaties en het vertrouwen van de klant.

Veelgestelde vragen

1Zijn deze bollards geschikt voor offshore-omgevingen?

Ja, ze zijn speciaal ontworpen voor offshore en zware scheepstoepassingen.

2Wat is de maximale beschikbare laadcapaciteit?

Standaardproducten zijn beschikbaar tot 2000KN, met hogere capaciteiten op aanvraag.

3Hoe presteren de bollards bij extreem weer?

Ze zijn ontworpen om met sterke winden, golven en stromingen om te gaan zonder dat de structuur in gevaar komt.

4Is er extra corrosiebescherming beschikbaar?

Ja, verbeterde coatingsystemen kunnen worden gespecificeerd op basis van de ernst van het milieu.

5Hebben deze bollards speciale fundamenten nodig?

Voor zware toepassingen zijn doorgaans versterkte betonnen funderingen nodig die zijn ontworpen om aan de belastingsnormen te voldoen.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!